Spira-trol™ by Spirax Sarco shipped faster than ever!

Orders filled in four days or less, with over 80% of valves shipping in 48-72 hours.

Spira-trol™ valves leave the Spirax Sarco USA factory pre-commissioned for applications, enabling quick ‘plug and play’ installation. With over 2,500 configurations available and shipping within 4 days, it is possible to match almost any system’s needs and bring it back into service as quickly as possible in the event of a breakdown.

Spira-trol™ valves leave the Spirax Sarco USA factory pre-commissioned for applications, enabling quick ‘plug and play’ installation. With over 2,500 configurations available and shipping within 4 days, it is possible to match almost any system’s needs and bring it back into service as quickly as possible in the event of a breakdown.

Frank P. Langley, Co., Inc. is your source for Spirax Sarco products in Western NY, Central NY, and the Southern Tier.

Both electrically and pneumatically actuated Spira-trol™ valves from 1⁄2” – 4”, up to flanged ANSI 150 versions are available on 4 day lead-times, for more details see the Quick Ship Core Range Matrix. With the complete Spira-trol™ range extending up to 8” and ANSI 600 pressure envelope, Spirax Sarco can offer control solutions from HVAC, through process and power, to severe service applications.

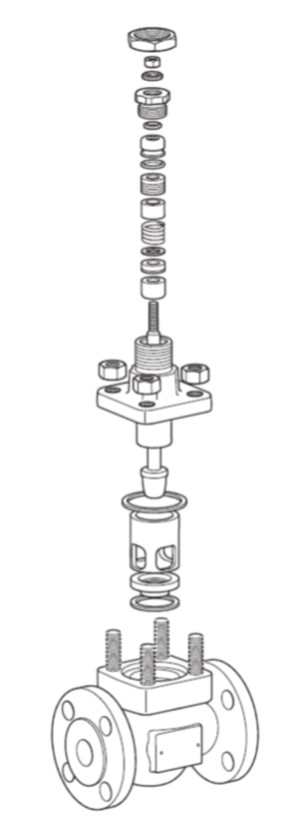

Spira-trol™ modular design, with quick-change ‘clamp-in-place’ seat, means its duty can be altered to match changing plant conditions, rather than replacing the entire valve. The self-aligning ‘clamp-in-place’ seat also simplifies maintenance, so there is no need for special tools and there is no need to take the valve out of the pipeline. This achieves considerable cost savings over conventional designs with screw-in seats, which often seize in place and require the valve removal, incurring a lengthy plant shutdown.

Spira-Trol™ diagram

Hassle free – quick and easy installation and low maintenance requirements

Self-aligning, clamp-in-place internals avoid the difficulties caused by conventional screw-in seats that can seize in place requiring the valve to be removed from the pipeline, causing lengthy shutdown.

All trim components are designed to clamp in place so the valve can quickly be configured to the user’s specific process needs. During assembly the seat and plug are self-aligning using the clamp in place cage retained design. The simplicity of build also means that maintenance is quick and easy, with no special tools required.

Increased stem seal life

Top and bottom guided valve stem ensures excellent alignment and long stem seal life. Scraper and dust rings ensure the stem seal is not damaged by the flow media or particles form the atmosphere. Viton ‘O’ rings ensure excellent sealing in low pressure and temperature media.

Long-life valve internals

When compared to alternative designs, the cage retained seat and plug of the Spirax Sarco Spira-trol™ provides the user with better valve shut-off performance and reduced leakage across the seat. Hard trim materials as standard, designed for steam, giving a high resistance to erosion and corrosion on an extensive range of media. Large gallery area reduces the flow velocity, body erosion and noise output.

Flexible and adaptable to process needs

Spira-trol™ valves can also be reconfigured to suit new demands easily, while stockholding costs for spares are minimized because Spira-trol™ components can be used with several different valves. Appropriate for most industrial fluids, the Spira-trol™ Control Valve offers a single solution across your control valve applications.